spring used in coal crushers

when pulverizing coal what is a crusher use for? LinkedIn

2023年3月1日 group. When pulverizing coal, a crusher is used to break down the coal into smaller sizes suitable for transportation and processing. Coal crushers are machines that use impact, shear

en/spring used in coal crushers pdf.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Henan Mining Machinery and Equipment Manufacturer

crushers used in coal mining industry. Spring Cone Crusher for sale price stone crusher for sale price Mar 27, 2014 Cone crusher is used in coal industry and secondary

What material is generally broken by a cone crusher?

2023年3月2日 A cone crusher is typically used to break down materials such as rock, ore, and gravel. The material is broken down into smaller pieces by the crushing action of the

What are the requirements for a sand crushing plant?

2023年3月6日 The most commonly used crushers in a sand crushing plant are jaw crushers, cone crushers, and impact crushers. Screening Equipment: The crushed sand

en/stone used in coal crushers pdf.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Spring Used In Coal Crushers Pdf|Mining Equipment

2021年8月26日 Coal crushers are important auxiliary dynamic machines in thermal power plants and are used for crushing and processing raw coal. However, a coal crusher

spring used in coal crushers pdf

Typical Spring Unit for elastic support of a coal crusher Spring Support of Coal Crusher Foundations in Power Plants Coal crushers of all types such as ring granulators

Spring In Coal Crushers stone used in egypt

Indeed, whether it is an underground coal mine or an open-pit coal mine, these equipment can adapt to the coal mine environment to stably carry out crushing operations.Cloud

spring in coal crushers

Spring In Coal Crushers stone used in egypt . Indeed whether it is an underground coal mine or an openpit coal mine these equipment can adapt to the coal mine environment to

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 This stone takes the speci c characteristics of pulverized coal room in ther-

Coal McLanahan

McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size. McLanahan crushers can take the coal producer through all stages of crushing process, from initial

Dynamic Characteristics of Crusher Supporting Structures

2021年4月12日 Crushers used in coal mills are of different types jaw type, cone hammer type, etc. Ring granulators a recent development in hammer type coal crushers are increasingly being installed in coal mills on account of their superior performance. They require minimum power per tonne of coal to be crushed.

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

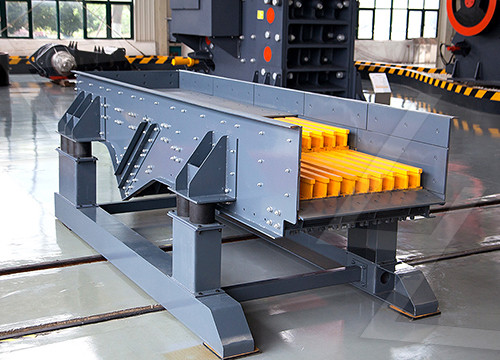

2015年4月10日 tie up. The received coal is sized in crushers (ring granulators) from (-) 300 mm to (-) 20 mm. Screens (vibrating grizzly type or roller screens) provided upstream of the crushers screen out (-) 20 mm coal from the feed and ( ) 20 mm coal is fed to the crushers. A set of rod gates and rack and pinion gates is provided before screens to permit

Types of Crushers Mineral Processing

2015年6月23日 The design scheme of crushers: 1 fixed cheek with the rotation axis; 2 a movable cheek; 3, 4 the eccentric shaft; 5 rod; 6 hinged rear bearing spacer cheeks; 7 spring; 8, 9 width adjustment

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

en/stone used in coal crushers pdf.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Roll Crusher ManufacturerDesign Williams

Use an Industry-Leading Roll Crusher on Your Next Job. The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining,

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 tie up. The received coal is sized in crushers (ring granulators) from (-) 300 mm to (-) 20 mm. Screens (vibrating grizzly type or roller screens) provided upstream of the crushers screen out (-) 20 mm coal from the feed and ( ) 20 mm coal is fed to the crushers. A set of rod gates and rack and pinion gates is provided before screens to permit

Double Roll Crusher Henan Deya Machinery Co., Ltd.

2012年7月30日 Double roll crusher working principle. Roll crushers, or crushing rolls, or double roll crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum

Types of Crushers: What You Need to Know Machinery

Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

How Do I Know Which Primary Crusher Is Best For My Coal

Generally, a Quad Roll Crusher is recommended for a medium size feed material, while the Triple Roll Crusher, with its single roll top stage, is effective for handling larger size feeds. These machines do the work normally assigned to two separate crushers. Typical feed sizes range from 18” 72” with final product size of ½” 3”.

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

Roller Crusher For Sale Double Roller Crusher Coal

The DR400 double-roll crusher is a track-mounted, self-driven, feeding, crushing and stockpiling machine for use in medium to hard bituminous coal crushing applications and is fitted with a purpose-designed 3636 double drum roll. Our double-roller crusher unit forms part of a comprehensive range of materials handling equipment including

Charcoal Coal Crusher Charcoal Powder

The charcoal coal crusher machine is mainly used to produce charcoal powder by crushing charcoal fragments, charcoal leftovers, finished charcoal, etc. The charcoal powder grinder machine is a device for

Crushers For Sale Near Me Equipment Trader

Packages starting as low as $29.95! Crushers are an important part of many industrial and materials processing projects. They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust. Equipment Trader’s website allows users to quickly search for the best models near to their zip code from the brands and dealers that